Aluminum Electrolysis Line

Aluminum Electrolysis Line

Min Aluminum is the sole enterprise now owning complete industrial chain of aluminum electrolysis and extrusion in one district.

All the primary aluminum with good quality would be used in production of aluminum profiles.

- Name of Facility : Pre-baked Anode Electrolytic Cell

- Facility Power : 240KA

- Advantages : high capacity, high efficiency, low consumption, low pollution etc.

- Annual Capacity : 250 thousand tons of aluminum electrolysis

Aluminum Casting Line

Aluminum Casting Line

Adopting advanced internal-led hydraulic and airslip lubricated casting technology from USA, Min Aluminum has been engaged in aluminum smelting and casting for long term.

Min Aluminum is the largest aluminum profiles manufacturer producing aluminum billets by liquid aluminum directly in China. The industrial chain of aluminum electrolysis and profiles has remarkable effect of energy saving and emission reduction

Annual capacity: 250 thousand tons of aluminum billets

Alloy kinds : Covering from 1*** to 7*** alloy series.

Max diameter of billet : ∮381mm.

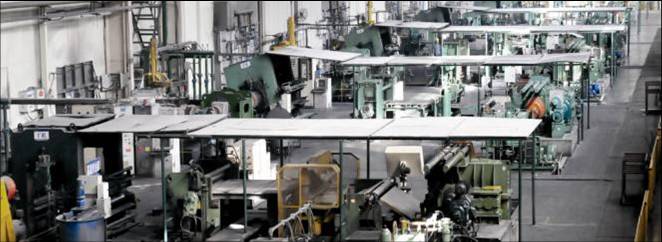

Aluminum Extrusion Lines

Aluminum Extrusion Lines

Min Aluminum has been engaged in aluminum extrusion production for about 30 years. Min Aluminum imported the first press line from Italy marked DANIELI brand since 1983.

Extrusion Lines Q’ty : 56 lines

Main Facility Models : 16MN / 27MN / 38MN / 55MN and so on.

Facility Place of Origin : Germany, Italy and America

Annual capacity: 250 thousand tons

Production type : precision tubes, bars, rods and profiles for different applications

Min Aluminum is adopting advanced technical processes on extrusion such as gradient heating of billets and isothermal extrusion of profiles and equipped with quenching devices of water, frog and wind at exit, the productive process could be controlled well and all various of tubes, rods, flat bars and profiles applied in many fields with high precise. The annual capacity reaches 150 thousand tons

Surface Treatment Lines

Surface Treatment Lines

Surface Finishing Types :

Anodized

Electrophoresis coating

Colorful electrophoresis

Powder coating

PVDF coating

Thermal break of barrier strip

Thermal break of pouring

Wood-like transfer printing etc.

Finishing Line Q’ty : 24 lines

Annual Capacity : Over 200 thousand tons

Facility Brands and Place of Origin :

Brand AUTEL of Italy

Brand ALMEX of Japan

Brand ALTEC of Italy

Brand RANSBURG of Japan

Brand FOM and DECORAL of Italy ( thermal break lines and wood like transfer printing )

The main raw materials of electrophoresis paint, PVDF paint, powder, barrier strip and polyurethane glue etc. are all with international famous brand covering KANSAI, PPG, AKZO, TECHNOFORM and AZON.

Aluminum Sheet & Strip Lines

Aluminum Sheet & Strip Lines

Min Aluminum has formed complete industry chain of aluminum sheet & strip including aluminum casting / aluminum sheet & strip / colorful coated aluminum sheet.

Production Line Q’ty:

Rolled Casting Line : 6 lines

Cold Rolled Line : 2 lines ( high-precision )

Rolling Painting Line : 1 line

Coating Line : 3 lines

Fabrication Line : All series of NC metal fabrication lines

Other Lines : Recoiling Dividing, Slitting, Transverse Cutting, Tension-Leveling, CNC Rollers Grinder

Production Specifications:

Max Width : 1850 mm

Max Thickness : 5~8 mm

Max Roll Weight : 11 tons

Annual Capacity :

Rolled Casting Strips : 60 thousand tons

Cold Rolled Sheets & Coils : 80 thousand tons

Rolling Painting Strips : 15 thousand tons

Fabrications : 500 thousand square meters

Coating : 2000 thousand sqare meters

The products of company could be applied to many fields, such as packaging, printing, electron, mechanism, electrical appliance, communication and architectural decoration etc.

Products include aluminum cast-rolling strips, curtain wall panel, universal panel, high precision aluminum plate and strip (plates, foils).

Products Applications:

Packaging, Printing, Electro Mechanism, Electrical appliance, Communication, Architectural Decoration

Dies Making Center

Dies Making Center

Production Line Q’ty:

CNC : 6 ea

NC Milling : 5 ea

Forming : 7 ea NC DEM

Wire Cutting : 9 ea NC EDM

These machines are from USA, Japan and Korea etc., and use 3D measurement instruments with high precise by NC improvement to realize complete NC fabrication of dies.

Further Machining

Further Machining

Min Aluminum is covering about 20 thousand square meters of comprehensive workshops for modern precise fabrication of aluminum products.

We are owning all types of production equipment for further processing, such as cutting, punching, milling, drilling and lathing etc. Our capability of design and fabrication reaches to 6000 tons.

During the past ten years, Min Aluminum was specially engaged in aluminum further fabrication, researches, production and sales relating to solar frames & brackets and solar PV module products.

Min Aluminum could provide finished or semi-finished aluminum products to some industries covering

solar PV, body of traffic vehicles, mechanism, electricity, electronic communication, many down stream consumption fields.

Main Products:

microwave heat sink

bumper of automobile

aluminum circle plate

punching pieces of irregular slab

shelf of integrated cabinet

aluminum components of solar series etc.

Aluminum Window&Door / Curtain Wall Lines

Aluminum Window&Door / Curtain Wall Lines

Min Aluminum could take design and construction for high-grade decoration of inner and outer room in all types of buildings.

We develop new products and new technology owning specialization team with rich experience of building decoration and construction.

We have the capability of completion with good quality in high speed for decoration projects of large buildings.

Annual Machining Capacity :

Curtain Wall : 200 thousand square meters

Door and Windows : 300 thousand squrare meters

Al – Wood Composite Window : 120 thousand square meters

Link: Industry Platforms