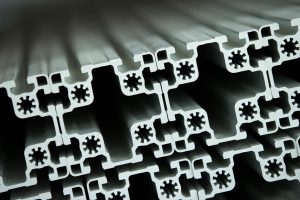

Aluminum extrusions

Aluminum extrusions

We possess an extensive portfolio of extrusion and drawn tubing capability. Our profile design and alloy designations consistently meet stringent quality and market demands.

We possess an extensive portfolio of extrusion and drawn tubing capability. Our profile design and alloy designations consistently meet stringent quality and market demands. Aluminum plate

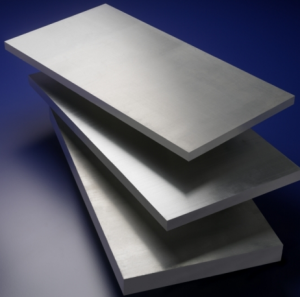

Aluminum plate

The aluminum plate produced by Min-aluminum can be used in tooling plate, equipment working tables, pharmaceuticals, machining fixtures, computer & electronics, jigs, index tables, mould cooling & heating plate, template, industrial robot and printing machinery, medical applications, vacuum chucks, food machinery moulding plate, packaging machinery, semi conductor parts, automotive, base plate, thermo forming.

The aluminum plate produced by Min-aluminum can be used in tooling plate, equipment working tables, pharmaceuticals, machining fixtures, computer & electronics, jigs, index tables, mould cooling & heating plate, template, industrial robot and printing machinery, medical applications, vacuum chucks, food machinery moulding plate, packaging machinery, semi conductor parts, automotive, base plate, thermo forming.The hot-rolled plate that is milled flat and parallel on both faces. It is an excellent option for applications that require close tolerance and strength such as high-precision structures, guide systems and sizing jigs.

The hot-rolled plate made with a heat-treatable alloy that incorporates good shape stability, excellent surface finish, and the lightest dimensional tolerances. It is the cost-effective solution for applications requiring the highest degrees of strength and precision.

Aluminum alloys for casting and tooling

Aluminum alloys for casting and tooling

Some kind of casting aluminum alloy is offering excellent machinability for short chips, these cast plates are much suited to anodizing treatments. Because of its excellent machinability, it is the cost-effective solution for applications requiring low strength levels and high shape stability during and after machining.

Some kind of tooling aluminum alloy is offering easy machining, dimensional stability and corrosion resistance. Additionally, it presents an ideal solution for machine tables and other parts requiring a high strength-to-weight ratio. It is suitable for tooling base plates for die cutting, cutting and stamping of tool parts, mobile machining assemblies for CNC machines, mechanical parts requiring a high strength-to-weight ratio (such as robotic parts and special machinery), and machine tables.