Min-aluminum’s high-dissipation heat sinks utilize aluminum’s excellent natural heat conductivity properties to dissipate heat in a variety of everyday applications in the area of renewable energy, transport, electronics and electrotechnics.

Cooling off

Cooling off

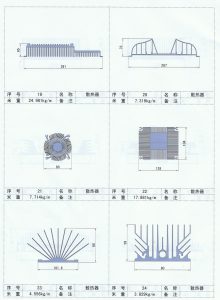

The efficiency of a heatsink is largely determined by its surface area so that a large number of fins with small spacing are desirable. Conventionally extruded heat sinks are inadequate to meet this requirement.

Our plant has therefore developed various patented shapes and manufacturing techniques for heat sinks over the past 20 years that fulfill the demand of a maximum surface area.

Maximizing conductivity

Maximizing conductivity

The distinctive feature of Min-aluminum’s high-dissipation heat sinks is that the baseplate and the fins are extruded separately and then assembled mechanically by

means of a special tool.

Using a modified technology that allows for a clear fin spacing of 2.5 mm, partial cold pressure welding joints are achieved in addition to the mechanical bond.

Min-aluminum’s high-dissipation heat sinks manufactured to the new technology, offer substantial technical and economic advantages as a result of the following features:

- High cooling performance due to the very large surface area of the fins and small spacing between the fins

- Favourable weight/performance ratio

- Low die costs

- Numerous possibilities to adapt the system to each use

- Many variations can be achieved by combining different base and fin sections

- Partial assembly of base section is possible across the width and the length

We provide custom aluminum extrusion , CNC machining, surface finishing service, it’s real one-stop-shop to you.