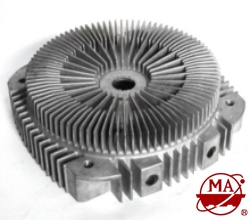

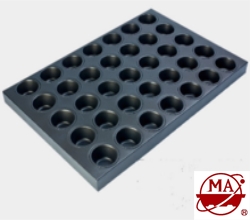

There are many reasons aluminum is the most commonly cast non-ferrous metal in the world. It’s light, strong, corrosion resistant, non-staining, highly conductive, non-magnetic, accepts many finishes and is cost effective. Since die casting aluminum alloy is 95% post-consumer recycled material, aluminum die castings are green and sustainable.

The die casting process is based on rapid production that allows a high volume of die casting parts to be produced very quickly and more cost effectively than alternative die casting processes. Aluminum die casting tools last between 50,000 and 400,000 shots, depending on the application and class of the tool produced. Add these factors together and you will see why aluminum die casting has become the favored option for buyers worldwide.

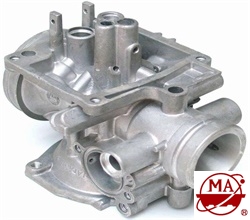

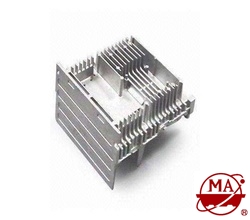

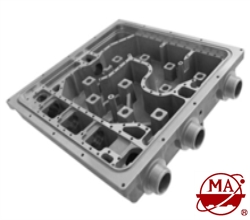

Min-Aluminum’s capabilities in die casting aluminum are unmatched. Considering our footprint, the industries we supply, our years of experience and our manufacturing capabilities, you will find that Min-Aluminum offers advantages beyond any other die casting company in the industry. Min-Aluminum has aluminum die casting machines ranging from 350 to 3,500 tons, giving us the ability to provide a large range of casting sizes and weights to serve nearly any industry and application.