A dedicated Min-aluminum extrusions unit for rail and bus offers a wide range of components and solutions based on aluminum extrusions.

Specialized products for a significant market

Specialized products for a significant market

Min-aluminum pioneered large-extrusion technology for welded aluminum railcar body shells and introduced the fully bolted standard system for bus superstructures. We have improved our processes and products ever since.

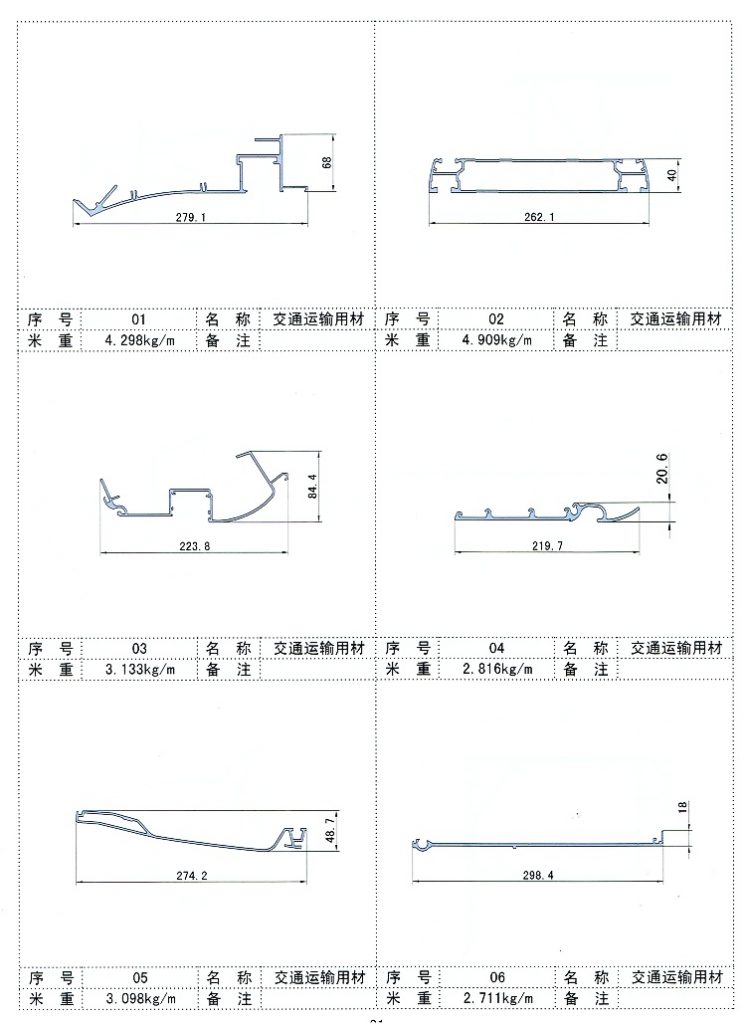

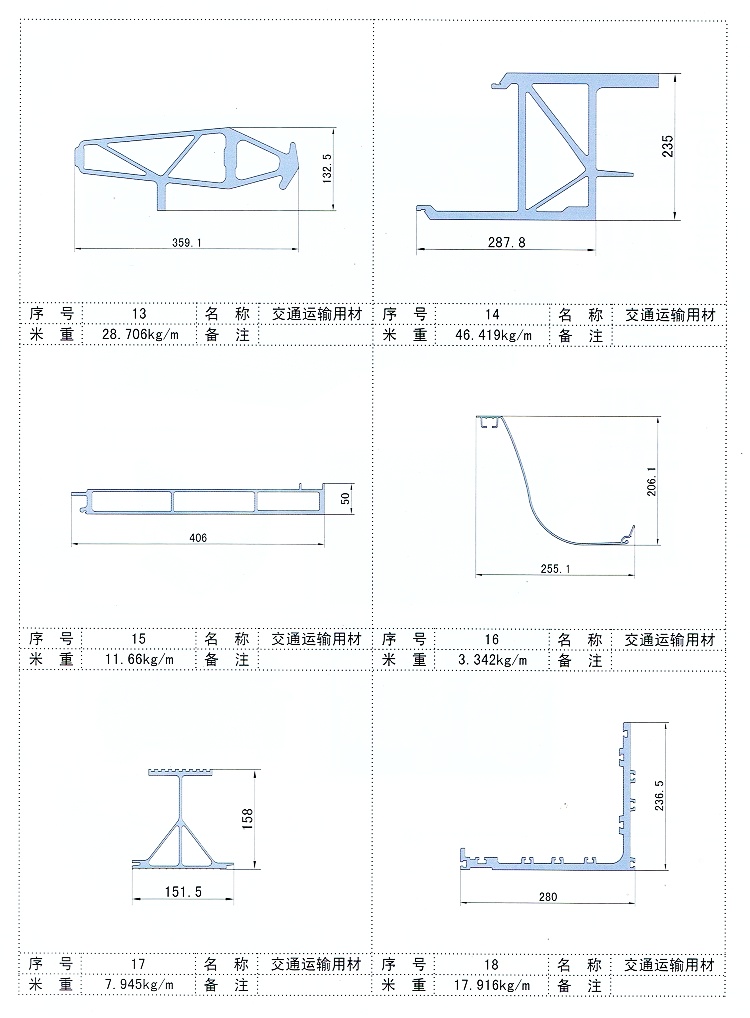

Our specialized product offer today includes:

- Structural extrusions for rail and bus applications

- Completely welded sub-assemblies such as structural floors, roofs, side walls and intermediate floors, for all

types of rail vehicles

- Finished, ready-to-mount and welded solutions, provided with all necessary cut-outs, fixations for seats and surface treatments, significantly reducing the customer’s production time

- Concepts and solutions that mechanically join different materials and patented resilient mounts

- The body structure system for bus builders, which combines standard structural components and bolted

connections based on proven aluminum and composite design in order to develop, design and build lightweight and cost-efficient

bus and coach bodies

Added-value services

Added-value services

In addition to our portfolio of products, components and solutions for rail and bus, Min-aluminum offers additional services such as:

- feasibility studies

- support for optimization, design and finite element analyses

- crash calculations

- support for static and dynamic tests of full-size body shells

- production assistance on customer premises